Do It Yourself / Make Your Own Gear

- Sewing projects

- Leather projects

- Rope projects

- Thermoplastic projects

- Composite material projects

- Other Projects

- (most used) Tools

- Materials List

- Suppliers

Sewing projects

One of the advantages of making my own gear is having the opportunity to tailor projects to my specific personal needs. Below, you’ll find projects I finished, based on my own practical needs.

Abisko Waterproof Jacket

Based on the Shelby Abisko Jacket Pattern, offering a shaped hood, shoulder and elbow patches, pit zips, shaped sleeves with adjustable hook-and-loop cuffs and large chest pockets. I made this waterproof jacket for hiking purposes, not including the pit zips and chest pockets, because they would be inaccessible wearing a backpack and chest pack. The Abisko Jacket must be amongst the best patterns available. The pattern is straight forward with plenty of options and easy to make for an intermediate sewer. The materials I use are the following:

- Laminated three layer (3L) fabric, 195 g/m², in blue and black. This slightly stretchy waterproof/breathable fabric consists of a durable polyester surface layer, a breathable PU membrane and an inner tricot into one laminated fabric. It has a breathability of more than3000 g/m2/24h and handles a water column of 10 000 mm.

- 3-Layer Seam Tape, 22 mm, in black. This an easily iron-on seam tricot tape, compatible with the above mentioned fabric.

- YKK AquaGuard® 3C Water-Resistant Separating Coil Zipper, 80cm, Lightweight water resistant 4 mm zipper, ideal for these types of lightweight shell jackets.

- 2 Duraflex Euro Cord Locks, for the hood cord, for which I used a piece of black 5mm Dyneema cord I had left.

- The logical thread would be alike the Gutermann Mara 50 thread, which can withstand the friction and rubbing of a heavy backpack easily. I used the Amann-Mettler Xtreme Pro thread, no. 40, in matching colours. A slightly over the top thread for a jacket, but I like the solid feel of the finished seams.

I find the one-stop shopping at the Shelby Outdoor online store to be super convenient. Receiving one package with all the required components for a project, from start to finish, results in an immediate worry-free start!

Koruoma Technical All-season Hiking Pant

I used the Korouoma Pant Pattern, offering a multiple pocket options, shaped knees, cuff reinforcements and snow cuffs make this a very versatile pattern; from light summer pants, to waterproof rain pants and lined winter hiking over pants. I made these for hiking purposes, trying to keep it as basic as possible. The functionality I was looking for was a simple lined waterproof pant, with two chino front pockets and one back (double welt) pocket. The fly is fake, but looks good. 🙂 The pattern is straight forward with plenty of options and easy to make for an intermediate sewer.

The materials I use are the following:

- Action Eco (2L) 160 g/m² fabric, a lightweight and waterproof shell clothing fabric. Nice, soft and flexible to touch. High-tech breathable shell material with two-layer construction where waterproof layer is coated on the lining side of the fabric.

- Orneule Oy Mesh Lining, a top quality soft mesh lining for technical hard shell clothing. Lightweight with a smooth feel to the skin. Ideal for lining 2L waterproof-breathable or other shell materials.

- Action 2-Layer Seam Tape, for waterproofing the pants. This basic seam tape is easy to attach with a regular clothes iron. Made for use with our Action fabrics and other 2L shell materials or fabrics with PU or PVC coating on the backside.

- Gutermann Mara 50 thread, which can withstand the rigours of trekking life.

I find the one-stop shopping at the Shelby Outdoor online store to be super convenient. Receiving one package with all the required components for a project, from start to finish, results in an immediate worry-free start!

Molle & Ripp-Off OuchPouch

I am a former (Green Baret) Commando Medic, as well as a AWRFA (Advanced Wilderness & Remote First Aid Medic) and Whitewater Rescue Technician (Rescue 3 Europe Whitewater / WRT-REC & WRI Swiftwater). My specific level of knowledge, reflects in the very particular contents of my First Aid kit, aimed to help myself and others.

This tailored rip-off First Aid Bag will be fitting neatly on my Fenix Protector ‘Magnus 50’ backpack, by 3 (out of 5) Pals straps. The main material is 1100 dtex Invista Cordura. The pouch measures 23 x 23,5 x 7cm. It has a Fidlock V-buckle.

The fixed base, that attaches to the pack has a rain flap on top and 3 ways of securing the pouch:

- by a strap connecting the flap (made rigid with Curv 0.66) to a bottom wedge.

- by a Curve (1.0) tongue sliding into the back of the pouch.

- by a Velcro strip

So the Pouch back corresponds with the fixed part, by means of a pocket for the tongue and a Velcro strip. It has a handle as well.

The front of the pouch has pals webbing to accommodate gear like a Tourniquet holder and a Leatherman Rapture Rescue tool .

The interior of the pouch is designed to fit my specific tools and medical contents. The insides of the shell parts and the detachable insert are all made rigid with Curv 0.66.

The compartments are made with elastic webbing, combined with Power Mesh. Some compartments have elastic webbing running over them as well.

Crampon Pouch

Most commercially available Crampon pouches are not fitted exactly to the product. My need for a small pouch made me make one. The challenge was to make it sturdy enough to withstand the penetrating force of the spikes when squeezed within my backpack. The outher fabric is 1100 dtex Invista Cordura. The binding is woven Polyester binding tape 25mm, sewn using a folding attachment on my machine, with Gütermann Mara 70 thread. It closes with two YKK no8 zippers and the attachement loops are made using Polyamid Webbing Black 8 mm, woven.

The upper and lower lining is a 450g/m2 Carbon Leather Fabric (basically a 400g Twill 3k Carbon Fibre Cloth with PU coating), sewable and with loads of abrasive resistance. It is safe to work with because the PU prevents the carbon fibers from coming loose.

Waterbladder Pouch (Insulated)

I made this tailored pouch to fit my Source WXP Low Profile 3L Hydration Bladder neatly in my Fenix Protector ‘Magnus 50’ backpack. The main material is 560 dtex Invista Cordura, used in two layers, with an isolating layer of foil wrapped 3mm XLPE foam insulation (cross-linked polyethylene foam) in between. It attaches to my pack with two webbing clips, using Polyamid Webbing Black 19 mm (0.75″), woven loops.

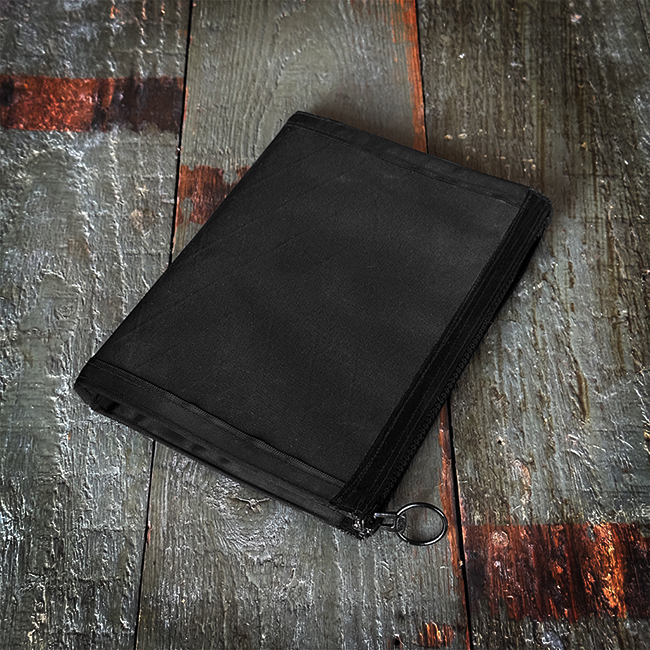

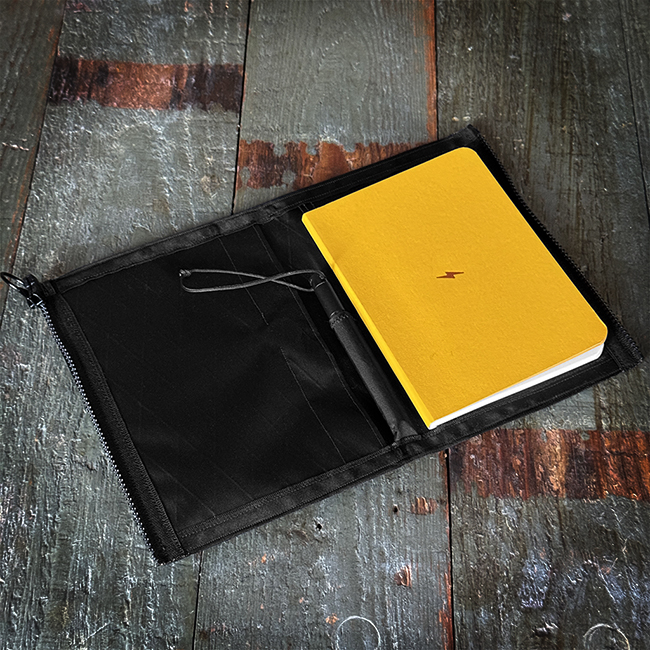

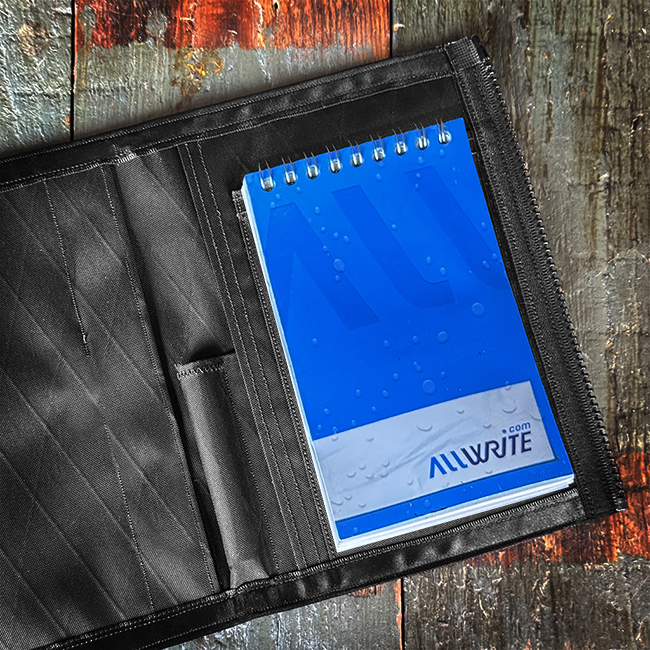

A5 Notebook Pouch

In need of a notebook cover to accompany me on my outdoor adventures, I made this multifunctional A5 pouch. It can hold a pen, an side bound notebook or a top bound notebook and it has a pocket for loose items.

As main material I have chosen Black VX21 X-pac (210 Den Nylon & 50 Den Polyester). Both sides have Black Curv 0,66 sewn in, to add rigidity. The binding is woven Polyester binding tape 25mm, sewn using a folding attachment on my machine. I used Gütermann Mara 70 as thread. The pocket closes using two magnets.

My main need was to make it fit Leuchtturm A5 softcover notebooks, which I use as standard. They are bound on the left side, which slides into a vertical opening. Along with that, the pouch has a horizontal slit to accommodate the use of AllWrite Waterproof Notepads, which are top bound. My pens are Fisher Backpacker Space Pens which can be used as full length pen and utilize Fisher Pressurized Cartridges, enabling them to write in rain, upside down and they can hang upside down forever yet function immediately when needed.

I chose to use a YKK no8 splittable zipper, because I like the feel of this type of closure, keeping the whole configuration rigid and sturdy. If opened, the slider is on the top left corner and it doesn’t get in the way (I’m right-handed.)

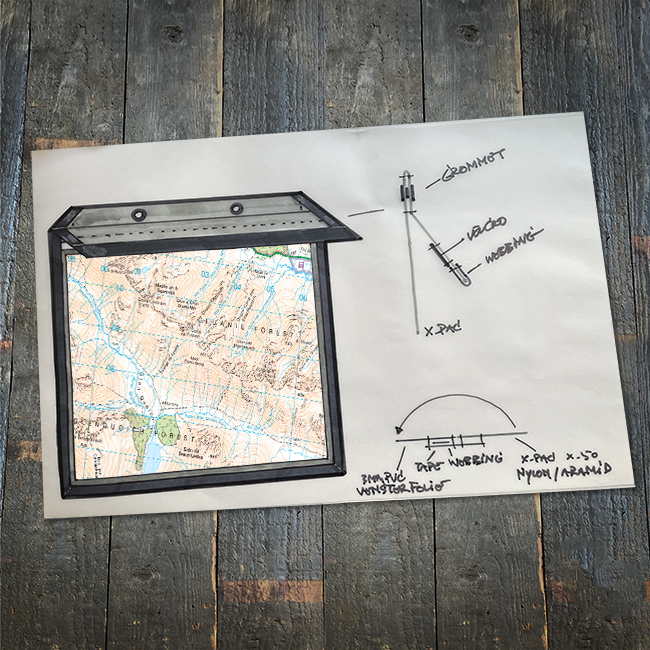

Map Case

There we go: an ultralight (as light as possible, yet durable) map case.

This case has tailored measurements, exactly serving the way I prefer to fold my (1:25.000 scaled) walking maps. Made of VX21 Black X-Pac® X4-Laminate with 210 den Nylon, X-PLY® and 50 den Polyester Backing, PVC Window Film 0,3mm and the top part is reinforced with Black Curv® thermo-polypropylene to create a sturdy base for the grommets and make the case stable to use. The binding is a 2,5cm webbing.

a Hand Muff

To protect myself from the effects of cold on my arthritis (or just for comfort), I made a muff. I take it with me to the golf course when it is very cold, or to occasions where I stand still in the cold for a long time.

I used a 12.5 cm sewer pipe as a form guide and chose materials that would provide a durable, waterproof and somewhat dimensionally stable sleeve. It’s meant to be worn around the waist, hanging on the bum and has a compartment for a heating pad or device. The belt is attached inside the cuffs to prevent the cuffs from being pushed inside along with the hands.

Materials & Components:

- 1100 dtex INVISTA CORDURA® PU-coated Black for the outer shell.

- 3 mm Neoprene Grey/Brown for insulation and shape.

- Faux fur, Black, long-hair for insulation.

- Heavy Mesh Black for the heating pocket.

- YKK Vislon 10VS, separating Zipper, single side opening, 15cm, but sewn with closed ends

- Elastic Ribbed Cuffs, Black

- Polyamide Webbing Black 25 mm (1.00″), wove for the belt

- WB25 Side-Release Buckle 2M Warrior-Series 25 mm (1.00″) Black

Bottle Harnass

On trips where water is scares, I often take a large (1,5 litre) Nalgene bottle as extra water storage. In search of the simplest way to carry these bottles, I made a harness for it, which (Molle) mounts to my backpack.

The entire harness is all 25mm Nylon Tubular Woven Webbing, apart from the collar fixation, which is 3,2mm Invista Cordura Truelock Elastic Shockcord.

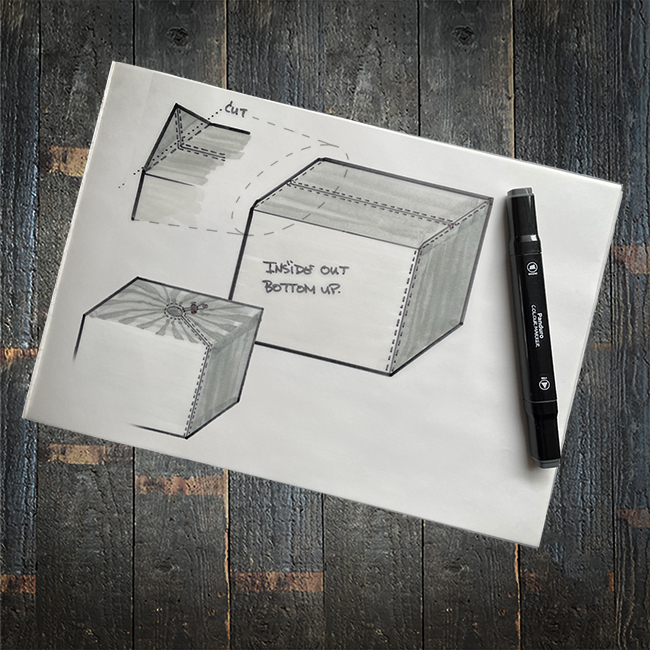

Packing Cubes

In an attempt to make the most of the space in my pack, I decided to make tailored stuff sacks for my Fenix Protector ‘Magnus 50’ backpack. With these cubes I utilise all the available space of this pack. I do not use them for trekking activities (because then I use a waterproof lining) but for travelling.

The choice for 50g/m2 Ripstop Silnylon fabric, is based on the weight and sufficient slipperiness, so that they stack easily in the backpack.

|  |

The basic shape is a trapezium/trapezoid, which I’d like to close with a centred drawstring. When I drew a (trial) pattern, it turned out to have a waving top to accommodate the trapezium shape. I have never seen a pattern like this before.

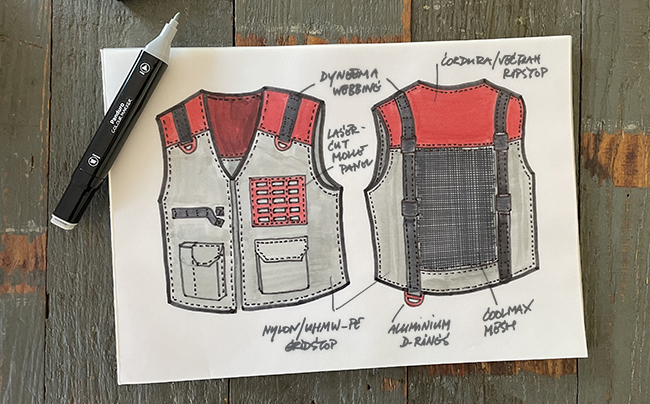

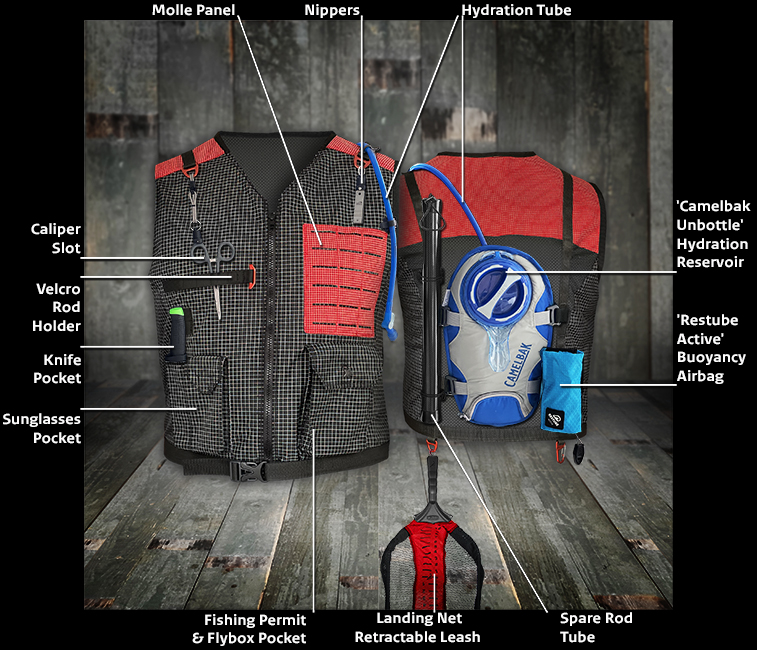

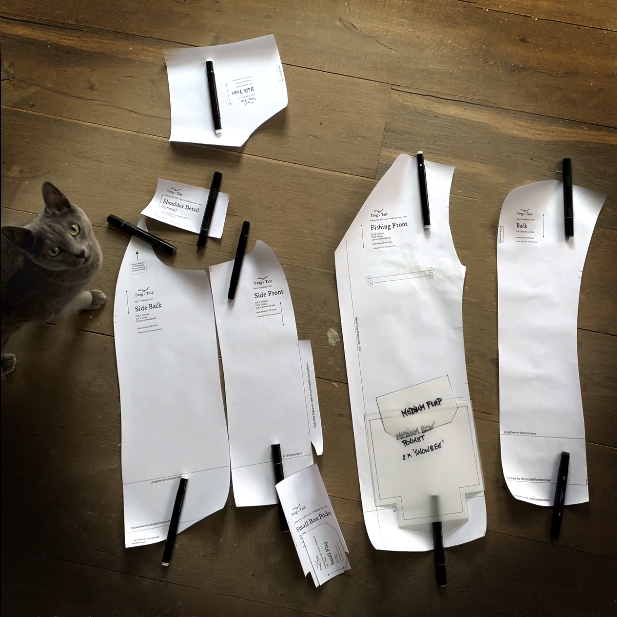

Fishing Vest

A fishing vest based upon the Twig & Tail Trailblazer Fishing vest, with a number of practical adjustments and additions. Our design goal was to make a light (less than 300gr), sturdy, low snag vest. I used the pattern for the basic shape and sizing. It is a 2 day project.

My version of this vest has:

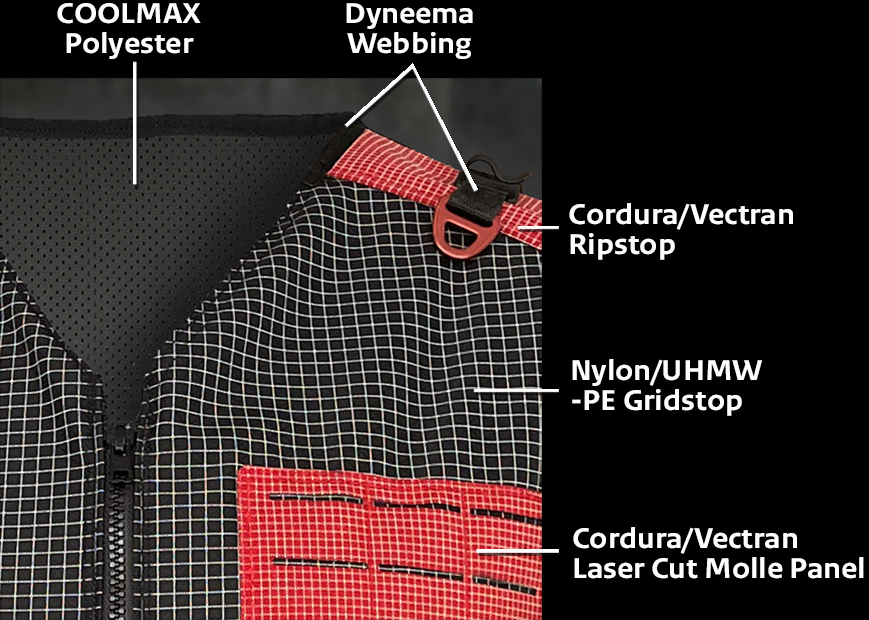

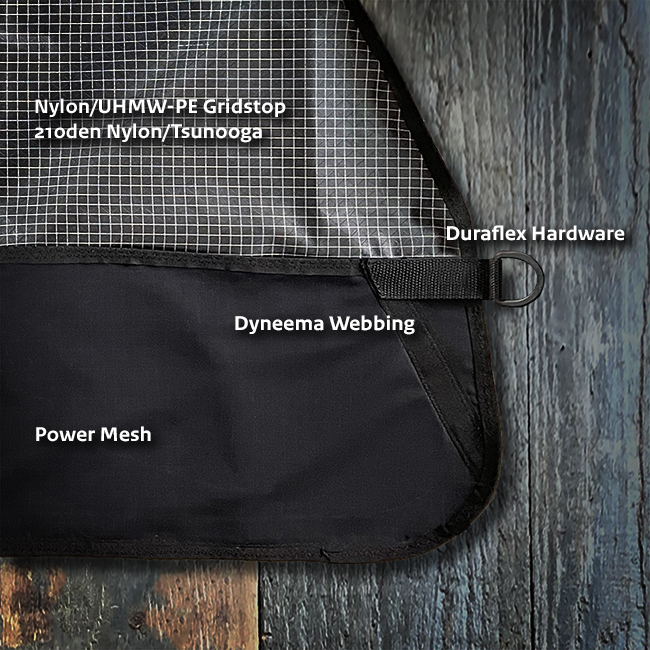

- a front panel made from Nylon/UHMW-PE Gridstop, 210den Nylon/Tsunooga, 160gr/m2

- an over-the-shoulder panel made from Cordura with Vectran-Ripstop, 410gr/m2

- a mesh back panel form COOLMAX-Polyester, 120m2

- webbing slots for calipers and a Rod Holder velcro fastner, made from 100% Dyneema, UHMW-PE, 100% SK75.

- a Molle panel, laser cut out of Cordura with Vectran-Ripstop, for whatever additional pocket or mount I need.

- a webbing ‘harnass’ from the front shoulder panel all the way to the bottom back of the vest, made form 100% Dyneema, UHMW-PE, offering anchor points for:

- a ‘Restube Active’ Buoyancy Airbag

- a ‘Camelbak Unbottle’ hydration reservoir and Hydration Tube Holder.

- a spare tenkara rod tube

- a D-ring to attach my ‘Ego Blackwater Trout Net‘.

Click to enlarge:

Techniques and materials:

- This vest has been sewn with a size 90 needle and Gütermann’s continuous filament thread, TERA 40, which is a Tex 75 polyester thread.

- I used Cordura with Vectran-Ripstop because of its strength and durability, so it can handle heavy backpacks. It is very hard to cut, so I used specialised micro-serrated scissors for the big Nylon/UHMW panels, but had the Molle-panel laser cut the Cordura/Vectran panels (based on a vector file). This was more exact and it sealed the edges.

- I made the left hand box-pocket to fit my fly-box and fishing permit. The right hand pocket has the same outher dimensions, but is divided into a sunglasses pocket with lid and a open knife pocket with a drain hole (with plastic eyelet).

- The Coolmax All Season Polyester mesh is used as lining for the vest, as well as a mesh back panel. A simple choice because of it cools in warm temperatures, insulates easily in cold weather and effectively wicks away moisture in all situations and dries quickly.

Polartec Raglan Hoodie

Here is my (raglan sleeve) hoodie. I used a pattern by Learn MYOG, The material I used is Polartec Alpha Direct, Style 4028 60g/m2. The Gütermann Mara 30 thread worked well with this fabric. My trial version, made out of unbleached cotton, did have details like the hood cinch and binding. None of those made it to the final version, due to lack of (base layer) functionality. I found it hard to use this material, because of the loose structure and the difficult to distinguish sides. Having said that: This turned out to be one of the most comfortable and warm base layers I own, despite it’s open structure.

This turned out to be a three hour project (trial version and my final version).

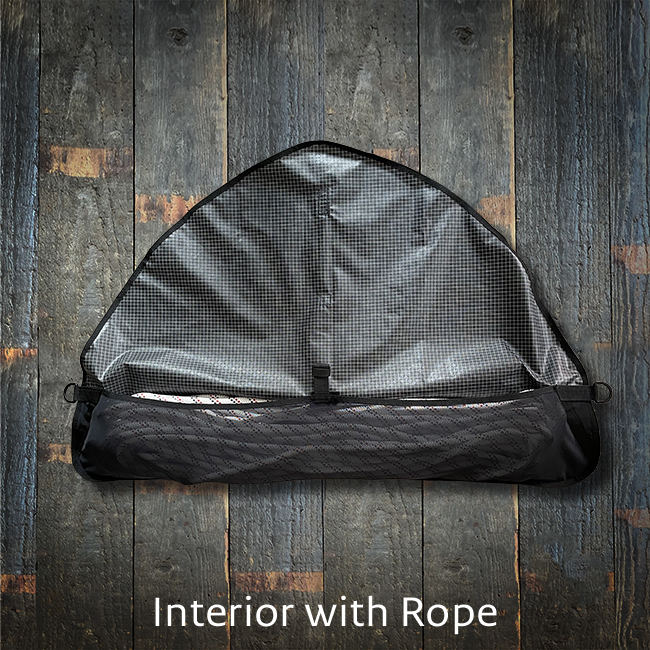

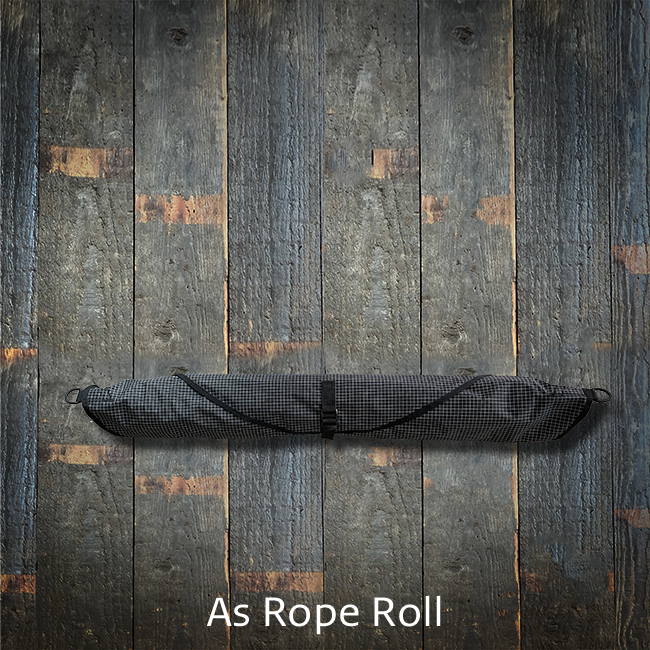

Rope Roll / Rope Tarp

This rope roll consists of an integrated bag and tarp and is elongated in shape when closed. It’s final shape fits on a Backpack Lid. The basic principle is to use gravity to lower the rope from the tarp into the shallow bag, which expands to fit the rope because it’s made out of Power Mesh. There is a piece of Velcro to secure the middle of the rope when rolling and/or to loop the rope end. Roll it all up and secure with one buckle. The two D-rings on the sides can be attached to the sides of the backpack. The dimensions are 100x100cm for a 30meter (9,5mm) rope, which I use for my walks. The outher shell is made out of Nylon/UHMW-PE Gridstop, 210den Nylon/Tsunooga®, coated, 160g/sqm. The inner pocket is made out of 4-way elastic Power Mesh. All hardware is Duraflex, all webbing is 100% Dyneema. It has a total weight 120gr.

Leather projects

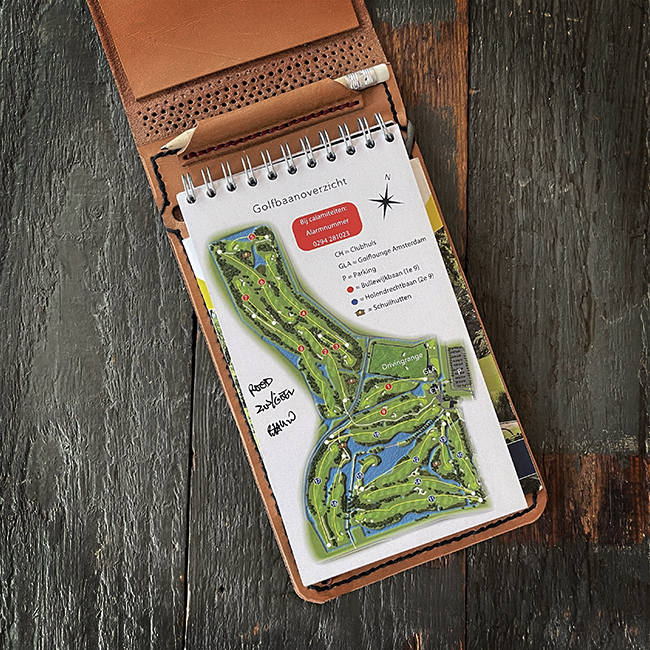

Golf Caddy-, Yardage- and Scorecard Book

I made this holder to keep all my golf administration together. It fits my back pocket, it has a pencil sleeve and the elastic page keeper and slots hold both a side-bound and a top-bound book. The leather is a piece of reused (cowboy)bag, veg-tan 1,5mm cow hide. It is entirely hand sewn using 6- and a 2 prong hole 1mm punches, wax-thread and a blunt needle. It took me 2 hour to make.

Knife Sheath

This sheath had to be made, replacing the 45 year old original that came with this Helle Camp knife. The knife is still in perfect condition, apart from some delamination, which is probably due to decennia of sharpening. (I made a kydex version as well.)

The sheath is made out of one piece of 3mm cowhide (a kids saddle found in a thrift store), thread and a brass button stud. It has two belt loops for a stable wear. I lined the sheath with a snug-fitting piece of 0,5mm G10 Micarta, folded on the edge side. The tools I used are a 6 prong 1mm punch, wax-thread, a blunt needle, a lined Basket Weave Brass Stamp for the decoration and a “V” Gouge for the decoration border. It took me an hour to make this beauty. I made a Kydex version as well.

Pistol Holster

This is the prototype of an bespoke made holster for some Walther P22 version. It is a belt worn, form fit, holster made out of 3mm cowhide, hand stitched using 6- and a 2 prong hole 1mm punches, wax-thread and a blunt needle. The decorative works as a pressure plate, covering elements that create the inward thickening, needed to keep the pistol in place. The basic shaping was done in a kydex press, moulding the wet leather. The whole holster is covered with a decoration made using a Basket Weave Brass Stamp. For the cover plate decoration, several Carving Stamp were used, either bought or home made. This holster took me a day to make, apart from the cover decoration which took another 4 hours.

Rope projects

DIY Tippet Holders

I’ve been looking for the simplest and lightest Tippet Holders for a long time. This is my solution:

Using half a (DAC) anodised aluminium pole repair sleeve (9mm inner diameter), a length of floating throw line end a lightweight (Wildo) plastic karabiner. By leading the rope ends through a centred hole in the pole and searing it around the pole end, I made these extremely light tippet holders.

Monkey’s Fist

This Monkey’s Fist, which is of no use to me, was a nice project to do. I used a glas marble of 6cm diameter, 6mm Hempex rope (a twisted, spun polypropylene artificial hemp rope) and an hour of my time. The knot used for the ball part is called the Monkey’s Fist knot (a throw line knot used on sailing ships and used as a melee weapon by the same sailors). For the handle I used a Crown Sinnet knot with an oversized Diamond knot on the end. All pretty basic knots. The hard part, as always with paracord projects, is to make the connections between the different parts/knots firm and solid. I solved the problem by incorporating the 2 handle ropes inside the Monky’s Fist knot. The Diamond knot was a continuation with the handle ropes. So plenty of rope should be used from the beginning.

Thermoplastic projects

Rogan Pry Bar Sheath

I made this sheath out of Black Curv® 0,66mm. An incredibly strong thermo-polypropylene material.

The pry bar does not pop or click into sheath. It is held in using an adjustable friction tensioner and slid into or pulled out of the sheath with a set amount of force.

Knife Sheath

This sheath had to be made, replacing the 45 year old original that came with this Helle Camp knife. I made a leather replacement sheath as well. This sheath was is a very basic kydex project. Two pieces of (carbon look) kydex, heated to 60° Celsius in the kitchen oven, moulded in a kydex press, riveted together (with a rubber washer for some tolerance in the shaping) and fitted with a belt clip. The rivets were set with a hand press, but these rivets can be bought with a manual rivet setter as well. This type of project is ideal to get familiar with kydex work. The only critical stage is the shaping, so the knife can be inserted and extracted easily, whilst being secure and silent when in place. This project took me an hour.

Composite material projects

Carbon Rod Tube

In need of a virtually indistructible, yet very light sheath for my fishing rods, I made this tube sheath that fits any of my Tenkara rods (snug):

- I shortened a piece round Carbon round tube, 3k-Plain Weave, Ø 30 / 28 (which I normally use to make kayaking paddles) to a length of 28cm.

- Plastic tube caps were added on both sides.

- The top cap was cut open, flush to the inside of the tube and thus creating some protection from the carbon edge.

- When placing the top cap I placed a loop of 3 mm elastic cord through it.

- A simple cord lock was placed on the cord.

- Two Elasto-Lok Ice Axle Buckles are added for mounting on a backpack or vest.

Now I simply slide a rod into the tube, though the elastic loop and tighten the cord lock.

Ready to go blue lining!

Other Projects

DIY Bee Wax Candle

Our all time favourite lightsource (and smell) must be the candle. I make mine by melting Wachsman Bee Wax pellets and a Candle Wick into an Elephant Box 50ml dressing pot. This wax is of a extremely pure medical quality. The pot has a silicon lid, which can be closed when warm.

(most used) Tools

Singer 4432 Heavy Duty Sewing Machine

My trusted sewing machine, a crucial factor in many of my projects! Capable of sewing outdoor fabrics, leather and what not. Components like feet, bobbins and needles are readily available. I almost always use it with the optional Singer Extension Table. This is an all mechanical machine. A choice I made so I can understand and feel the limits of the machine whilst challenging it’s capabilities. This is a very easy going, uncomplicated sewing machine, with straight forward features that cover all of my needs and much more. The available extra’s like feet and needles are easy to understand and use and explained in the projects that I’ll share and publish.

Kai Scissors & Shears

I am a loyal and very satisfied user of Kai scissors. These reliable Japanese high-precision tools make the most complicated work easy. Right now I’m using these scissors (from top to bottom):

- Stainless Embroidery Scissors 1140ST: 140mm total length, blade length: 55mm, with a soft elastomer handle. We do not do a lot of embroidery, but these are the best size to always have on hand when sewing on the machine.

- Stainless Universal Scissors 1165ST: 165mm total length, blade length: 65mm, with a soft handle grip. These are our all-round Sewing scissors with a useful compact, but potent, size.

- Stainless Sewing Scissors 1220ST: 220mm total length, blade length: 100mm, with a soft elastomer handle, angled to cut without lifting the material. Suitable to cut fabric, canvas and paper.

- Aramid Shears with micro serrated blade, 7240AS: 240 mm total length. The ultimate Aramid/Kevlar/Fibreglass scissors! The micro serrations ensure more grip on slippery materials and that the blade stays sharp longer. These micro serrated blades easily cut the toughest materials. A must have for making outdoor gear!

- Fabric Shears, 7300: 300mm total length. Long sharp shears, made to cut large pieces of fabric with ease. These are amongst the best in the world. The thick blades are made from particularly hard steel, called AUS8A, which is a stainless steel with a high carbon content. Due to this steel hey can be sharpened better and stay fine cutting much longer.

Special features of the 7000 series scissors are:

● The handle is made of soft elastomer which is a soft plastic type that gives the scissors a nice grip. Thus, it remains comfortable in the hand even during prolonged cutting.

● Thanks to the Duplex Interlock adjustment screw, these fabric shears are well adjustable and will not suddenly cut much looser after cutting through a heavy fabric. The scissors will always cut the same in terms of feel.

Kai Rotary Cutters & Cutting Mat

I use rotary knives for cutting technical fabrics, leather, paper, acetate and composite materials.

The two sizes I own are the Kai RS-45, ø45mm, size 180 x 55 x 30mm and the Kai RS-60, ø60mm, size 205 x 65 x 25mm. Both have three settings: light, heavy and secured. They come with a comfortable, soft-grip handle with a pressure-sensitive safety lock feature. The blades are made of tungsten steel.

A cutting mat is mandatory when using rotary cutters, because blade edges last much longer. My Kai CB-01N has the very practical dimensions of 900x600mm (and 1,5mm thick). This lightweight mat is made of 3 layers of PVC with a so-called self-heeling effect and can be used on both sides.

Prym Tools

Since Prym accessories are widespread and available, it is definitely worth having their VARIO Creative Tool. With this hand press and punching tool (and the necessary attachments) many accessories are very easy to mount. We use it for snaps, eyelets and rivets.

We use this Mini Steam Iron for every sewing project. Its user-friendliness and practical functionality usually wins over its big brother. Pressing small details, but also applying seam sealers are a piece of cake for this device.

Now this is one of those small tools that can make work so much easier: the Parallel Tracing Wheel. A real find! After determining and setting the distance, follow an edge or your pin row with this device and the chalk wheel will leave a razor sharp chalk line. Ideal for marking a seam width or adding a seam mark to a pattern.

The Prym Crafter’s hammer is a hard rubber mallet, suitable for all jobs that require some level of measured force. A ‘jack of all trades’ assistant for DIY projects.

Other Tools (Click to open)

Materials List

Layered/Laminated Fabrics

- Dyneema Composite Fabric (DCF/Cuben), 17.3 g/m² (Shelby Outdoor)

Ultra lightweight and totally waterproof fabric/plastic film like composite. Very strong for the weight on warp and weft direction. But as ultralight fabric it requires careful handling both when sewing and when using the gear. For seaming we recommend glue or both glue and sewing, perhaps with a additional strip for reinforcement. Tensile strength warp/weft: 552N/5cm, Tear strength warp/weft: 62N - Action Eco (2L) 160 g/m² with PFC Free DWR (Shelby Outdoor)

Lightweight and waterproof shell clothing fabric. Nice, soft and flexible to touch. High-tech breathable shell material with two-layer construction where waterproof layer is coated on the lining side of the fabric. Produced using recycled fibres. - Stretch Polyester Shell Fabric 190 g/m² with DWR (Shelby Outdoor)

Lightweight and stretchy twill fabric with soft feel. Excellent choice for jackets and pants. Tight weave provides good wind resistance without breathability limiting membrane. Durable Water Resistant (DWR) finish prevents water absorption. - 3-Layer (3L) Stretch WPB 195 g/m² with DWR (Shelby Outdoor)

Laminated three layer (3L) fabric for shell jackets and pants. Stretchy waterproof/breathable fabric which combines durable polyester surface layer, breathable PU membrane and inner tricot into one laminated fabric. This 3L fabric is great for durable shell jackets and accessories for wet weather use. - VX21 Black X-Pac® X4-Laminate with 210 den Nylon, X-PLY® and 50 den Polyester Backing (TacticalTrim)

X-Pac®’s lightweight 4-layer laminate with 210 den nylon outer fabric in colour Black. The waterproof fabric is ideal for making lightweight backpacks, panniers, packing cubes, bike bags, wallets or other lightweight but durable gear. The tried and tested X-PLY® technology creates a tear- and tension-resistant material. A 50 den taffeta nylon backing provides enhanced stitch hold. In addition, the light-colored taffeta offers the option of dispensing with the lining fabric on the inside of bags or backpacks. Laser-cuttable & waterproof. - Cordura® with Vectran®-Ripstop, honeycomb-coating, 410g/sqm. (ET)

Strong Cordura® with ripstop reinforcement made from the high-performance fibre Vectran®. The Vectran® additionally increases the tear resistance of the base fabric and, together with the white fibres, provides a technical look. With a strong, partial PU coating in a structured honeycomb pattern. Ideal for reinforcements or sturdy bags or backpacks.

Single Layer Fabrics

- Power Mesh (Discovery Fabrics) is a 4-way stretch fabric that has high compression. It looks like fine, stretchy netting. It is breathable and strong, but soft enough to be comfortable next to skin. 60″ wide, 230 gm, 4-way stretch: 50% in both directions. Certification: Bluesign. There are many possible applications, its just one of those handy fabrics we should always have in your stash!

- Silicone Nylon (silnylon ) Soar Coat Ripstop Discovery Fabrics)

65″ wide, 1.4 oz/sqyd or 50 gsm, no stretch, highly water repellent, very light and slippery. Ripstop Nylon is a woven fabric. It uses a special reinforcing technique that makes it resistant to tearing and ripping. Ripstop “stops the rip”. During weaving, reinforcement yarns are interwoven at regular intervals in a crosshatch pattern. Silnylon makes great stuff sacks or backpack covers. - Polartec Alpha Direct, Style 4028 60g/m2 (Discovery Fabrics)

this ‘active insulation’ fabric was developed for U.S. Special Forces to create an insulation that would be highly breathable as well as warm, fast-drying and became the ‘ultralight king of base layers’. - Merino Wool Tube Knit 19.5 Micron (Shelby Outdoor)

This thin 100 % Merino wool rib knit is perfect for tube scarfs, beanies and other small warm clothing. It works for both active sports and providing warmth over a long period of use. - Nylon/UHMW-PE Gridstop, 210den Nylon/Tsunooga®, coated, 160g/sqm. (ET)

The 210den nylon is reinforced with a white ripstop made from extremely tear-resistant Tsunooga® UHMW-PE-threads. A diagonal ripstop further enhance performance and give the fabric a technical look. Tsunooga®-UHMW-PE fibres, like Dyneema®, impress with their extremely high tear strength at low weight. Perfect for light to ultra-light backpacks, bags, hipbags and other outdoor gear. The thin, durable polyurethane coating makes the fabric highly water-repellent, but it remains pleasantly soft to the touch. - Mesh-lining, COOLMAX-Polyester, elastic, 120g/sqm.

Soft, elastic net-lining made from high-performance COOLMAX All Season, which thanks to a sophisticated fibre blend cools in warm temperatures, insulates easily in cold weather and effectively wicks away moisture in all situations and dries quickly. This is achieved by blending COOLMAX fibre, which is optimised for moisture transport, with hollow-fibres that provide insulation through the inclusion of air. Suitable as a breathable, fast-drying lining, for ventilation applications or as a very airy shirt on its own.

Tapes

- Stretch TPU adhesive film, heat adhesive (Shelby Outdoor)

Special adhesive film for bonding fabrics together without the need for sewing. Using a normal or hobby iron you will be able to bond almost all non-fleece fabrics (nylon, polyester, cotton, leather, membranes etc.) and e.g. zippers. - Action 2-Layer Seam (Shelby Outdoor)

Basic seam tape that’s easy to attach with regular clothes iron. Made for use with our Action fabrics and other 2L shell materials or fabrics with PU or PVC coating on the backside. In home use attach with a normal clothes iron at 120-140 degrees Celsius with a Teflon sheet or baking paper to protect the iron from glue. Glue is on textured matte side of tape. Meant for waterproofing sewn seams. - 3-Layer Seam Tape (Shelby Outdoor)

Seam tape for 3-layer fabrics. 22mm wide, use with any 3L WPB fabric. Apply with a normal clothes iron at 100 degrees with a Teflon sheet or baking paper to protect the iron from glue. Even white side has the glue surface. Power output on irons and material compatibilities may vary so try with scrap pieces first. Meant for waterproofing sewn seams.

Thermo plastics

- Black Curv® thermo-polypropylene (TacticalTrim)

CURV® is a stable thermoplastic composite material made of polypropylene with high energy absorption, high impact resistance and high impact strength. CURV® performs particularly well at extremely low temperatures with very good stability and, thanks to its resilience, the material always returns to its original shape. Thanks to the composite structure of the fibres, there is also no stress whitening (mechanical degradation). CURV® is chemically inert and impermeable.

Webbing, Rope

- 100% Dyneema® webbing, 20mm. Dyneema® fibres are 15 times stronger than steel, but still remain soft and textile. This webbing is 100% Dyneema®, so it is both very tear and abrasion resistant. Dyneema® is a very smooth fibre, therefore the surface of the tape is quite smooth. However, it still clings very well in our buckles. Ideal as an extremely tear-resistant, abrasion-resistant and UV-stable webbing or reinforcing tape. Thanks to its low density the tape floats and does not absorb moisture.

Other Materials

- YKK AquaGuard® 5C Water-Resistant Zippers (Shelby Outdoor)

High-tech water-resistant 6 mm AquaGuard zipper from YKK. This is used especially in lightweight 3-L waterproof-breathable clothing. Eliminates the need for multiple zipper cover flaps, but a simple flap protects the zipper from abrasion and prevents high pressure water from seeping through the zipper. - PVC Window Film 0,3mm (TacticalTrim)

Made of 100% PVC and weighs 365 g/m². This fabric-type is not IRR-safe, not PU coated, not DWR, water-resistant. This fabric has no stretch. Use it or Packs and Pouches.

Patterns

- Abisko Jacket Pattern (Shelby Outdoor)

The Abisko Jacket is a technical outdoor garment designed for non-stretch materials. It has a shaped hood, shoulder and elbow patches, pit zips, shaped sleeves with adjustable hook-and-loop cuffs and large chest pockets. The hem is long and can be finished with elasticated drawcord. Use waterproof-breathable materials to make a jacket for wet use or uncoated breathable materials for winter conditions. The Abisko Jacket has a relaxed fit for mobility and layering. - Men’s Korouoma Pant Pattern (Shelby Outdoor)

The Koruoma Pant is technical all-season hiking pant with a great shape, loads of customisations, yet it is easy to make. The wide elastic waistband and high back keep the pants up, and eliminate the hardest step in making pants: the zipper. The multiple pocket options, shaped knees, cuff reinforcements and snow cuffs make this a very versatile pattern; from light summer pants, to waterproof rain pants and lined winter hiking over pants. - Korouoma Jacket Pattern (Shelby Outdoor)

The Korouoma jacket is a modern outdoor requirement. Perfect for fleece, with pit zips, big breast pockets, shaped elbows and an adjustable hem. The pattern is very flexible, and can be used to make anything from a simple fleece jacket, to a very technical wind stopping shell. - Twig & Tail offers sewing patterns online, with every conceivable form of help on the website and included with the patterns.

- Learn MYOG designed and offers the famous Alpha Raglan Hoodie patterns. IMHO, Tim makes great choices in what he makes, uses and offers. A great place to visit for knowledge, patterns and inspiration!

Suppliers

- Shelby Outdoor is a Finnish supplier of both DIY as Ready-to-use gear.

- TacticalTrim is the German one-stop-shopping supplier of military standards or are based on a US Mil-Spec/German TL. DIY /MYOG goods, carrying a wide array of haberdashery, fabrics, webbing, zippers, Velcro, etc. Their website is in German and English.

- Discovery Fabrics: a Canadian company specialising in technical and performance fabrics for Outdoors and Activewear, selling high quality fabrics.

- Twig & Tail offers sewing patterns online, with every conceivable form of help on the website and included with the patterns.

- Learn MYOG designed and offers the famous Alpha Raglan Hoodie patterns. IMHO, Tim makes great choices in what he makes, uses and offers. A great place to visit for knowledge, patterns and inspiration!

- Duraflex is the brand I rely on for all plastic trimming products (readily available worldwide).

- R&G Faserverbundwerkstoffe GmbH is a German company where I get my high quality Carbon tubes.

Need information? Help? Feedback?

Check out the Tailor Forum.